|

We have summarized practical points when designing tension coil springs and determining drawing specifications.

Tension coil spring design 5 points

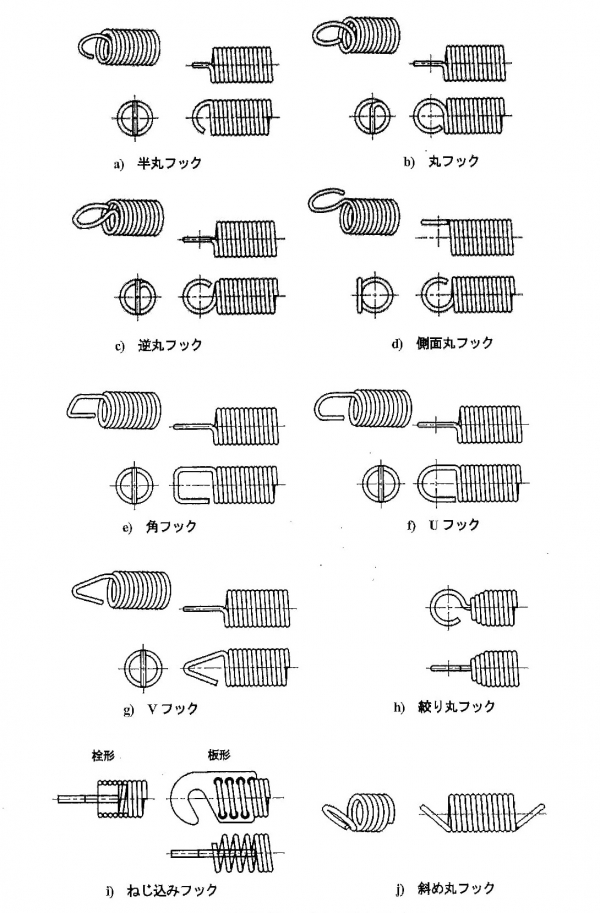

Point 1 Pull spring hook

Typical hook shapes for tension coil springs are as follows.

Please refer to the next page for the features, advantages and disadvantages of each hook.

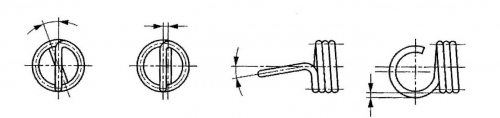

There are the following types of hook tolerances (variations).

From the left of the figure

① Variation in the facing angle of the hook

② Variation on the center line of the hook

③ There are variations in the fall of the hook

④ There are variations in the protrusion of the hook.

As a general rule, the parties will agree to enter the tolerance on the hook. Tolerances are not set in advance.

For spring characteristics (when specifying load and spring constant tolerances), hook dimensions are for reference only.

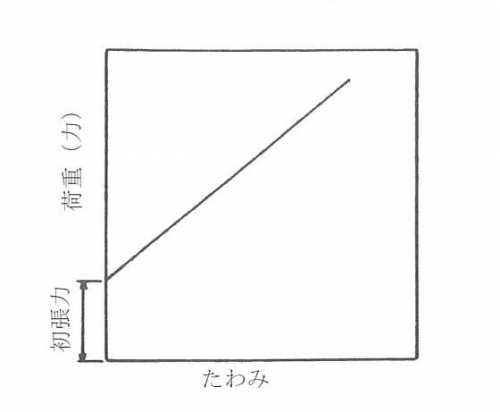

Point 2 About initial tension

Initial tension is generally defined as "the internal force of a tension spring that is in close contact with no load".

The pull spring is characterized by effectively utilizing the initial tension to save space.

The relationship between the initial tension and the load is as shown in the figure below, but the load is determined by how much clogs called the initial tension are worn. The stronger the initial tension, the more advantageous for space saving.

The initial tension can be increased or decreased depending on the processing method.

In many cases, the initial tension is increased in order to save space, but at that time, the following points should be noted.

(1) If the initial tension is too strong or too weak, processing will be difficult. There is a proper range. If it is set outside the proper range, it is necessary to make an agreement between the parties.

(2) The spring is tempered (low temperature annealing) after processing. In order to maintain a fairly strong initial tension, the temper treatment should be performed at a lower temperature (200 ° C to 250 ° C) than usual, or the temper treatment should be omitted.

In this case, the hook part is more brittle than usual and is easy to break.

(3) Temper processing removes the initial tension. How much it decreases depends on the material. The guideline for reducing the initial tension is as follows.

Hard steel wire / piano wire reduced by 20-35%

Stainless steel wire reduced by 15-25%

Please note that it is often designed without taking into account the decrease in initial tension due to tempering.

Point 3 Precautions when specifying tolerances for spring characteristics

The spring characteristics are (1) the load at the specified length and (2) the spring constant.

When deciding the specifications in the drawing, basically, the tolerance of "spring characteristics" is not specified.

If it is absolutely necessary to specify the "tolerance", specify the tolerance (tolerance) of "(1) Load at the specified length" of "Spring characteristics".

Furthermore, if it is deemed necessary, specify the tolerance of "②Spring constant".

If you specify a tolerance for spring characteristics, the free length is a reference value. There is no tolerance for free length.

If both "spring characteristics" and "free length" are tolerated, mass production may become difficult and costly.

Also, the specified load and spring constant cannot be specified anywhere the spring bends. There are the following rules.

"Rules for load when specified length"

Specify the specified length so that it is between 20 and 80% of the total deflection.

The load must be 80% or less of the maximum test force.

"Rules for spring constant"

It is calculated by "difference in load" ÷ "difference in deflection" at two load points at 30 to 70% of the total deflection.

The load must be 80% or less of the maximum test force.

Point 4 Spring index

The spring index is the average coil diameter divided by the wire diameter.

When written with a symbol, c = D / d. The spring index is also called D-by-D.

It is recommended to design the spring index in the range of 3-22.

Also, the tolerance range changes depending on the spring index.

If the spring index is too small or too large, workability becomes a problem, making it impossible to manufacture, increasing variation, and increasing costs.

Point 5 Other precautions

① Number of turns

The effective number of turns of the pull spring is the same as the total number of turns. However, the hook part is excluded.

If there is a tolerance in the spring characteristics, the number of turns is a reference value.

② Setting

The pull spring does not set. Generally, this is not done because the initial tension disappears when setting.

③ Painting

If there is a close contact coil part such as a pull spring, it is generally not painted.

This is because the film thickness of the coating is not constant and the spring characteristics are often not as designed.

In addition, since the film thickness is not formed at the close contact part, the rust preventive power may be significantly reduced.

④ Free length

The free length of the pull spring is the length from the inside to the inside of the hooks on both sides.

Note that the maximum length from one end to the other is not a free length.

The free length is a reference when allowing tolerances in spring characteristics.

If you have any questions about spring design, please feel free to contact us.

|

![]()

![]()