Rust and corrosion protection for springs

Since the materials used for springs have high strength, corrosion has a very large impact on strength.

Regardless of the spring, the surface of metal is unstable and easily changed, and reacts with oxygen, water, carbon dioxide gas, corrosive gas, corrosive liquid, etc. in the atmosphere and corrodes.

Basically, metal surfaces are unstable and change easily. It corrodes by reacting with oxygen, water, carbon dioxide gas, corrosive gases (such as chlorine), and corrosive liquids in the atmosphere.

The following are the conditions that promote rust generation.

・Since the rate of rust generation is proportional to the surface area of the metal, the rougher the iron surface, the faster the rust generation.

・Adhesion of foreign matter tends to condense moisture in the air and promotes the generation of rust. In particular, when hygroscopic foreign substances such as salt, paper, and fibers adhere to the surface, rusting is further accelerated.

・When the temperature of the air that touches iron changes (when the temperature drops), it is easy for rust to occur due to condensation.

Reference example of rust generation

If liquid water comes in contact, the reaction

Fe + 2H 2 O → Fe(OH) 2 + H 2 … ①

will occur and ferrous hydroxide will be generated. Furthermore, it reacts with water and dissolved oxygen in water to form ferric hydroxide, which is the main component of red rust.

Fe(OH) 2 + 1/2H2O + 1 / 4O2 → Fe(OH) 3

In addition, the hydrogen generated by formula ① combines with oxygen in the air to produce water, but some hydrogen penetrates the iron surface and causes surface embrittlement. is said to shorten fatigue life.

To prevent rusting, metal surfaces must be kept away from direct contact with water and oxygen.

For that reason, it is necessary to put a protective film on the metal surface to block water and oxygen, and at the same time prevent the invasion of salt, fingerprints, atmospheric gases, etc. that promote the generation of rust, and improve the durability of the metal. Says.

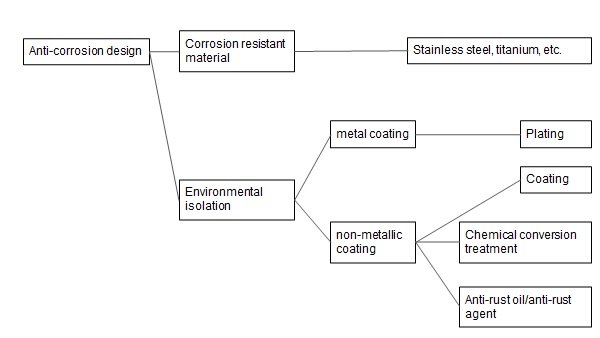

For this reason, when manufacturing springs, we incorporate "anti-corrosion design" as shown in the diagram below.

Outline of anti-corrosion design (simple)

*As mentioned above, if no plating or painting treatment is specified, we will apply anti-corrosion oil after production.

Anti-rust and anti-corrosion measures by materials

This is a method of manufacturing springs from corrosion-resistant materials. We have "stainless steel wire for springs", "plated wire for springs" and "titanium alloy for springs".

Example of corrosion-resistant spring

SUS304-WPB: This is the most commonly used material among stainless steel wires for springs . It is also characterized by having the highest tensile strength among spring stainless steels .

SUS316-WPA: A material with better corrosion resistance than SUS304-WPB . Another feature is that while SUS304-WPB is magnetic, this material is less magnetic.

Titanium alloy: Used in fields that require light weight and high strength, such as space development and aircraft.

Its corrosion resistance surpasses that of stainless steel, but it is a difficult-to-process material that is expensive and has limited applications such as eyeglass frames and golf gloves.

Click here for details↓(Japanese Page)

Anti-rust and anti-corrosion measures by isolating the environment

When using materials other than corrosion-resistant materials, this is a manufacturing method that uses anti-corrosion methods (painting, plating, chemical conversion treatment).

Examples of environment shielding (anti-corrosion method)

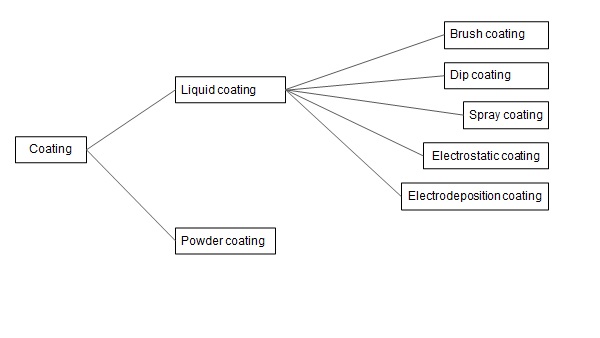

Coating : This method forms a coating film on the surface of the spring . This method is mainly used for compression coil springs. Adhesion springs (extension springs) are rarely used because the coating does not spread over the parts that are in close contact.

When painting, it does not peel off easily, has moderate hardness, elongation, and elasticity, and does not deform even when a little external force is applied. There is a condition that there should be no deterioration in luster or strength.

In addition, depending on the state of the paint, it is classified into two types of methods: liquid coating and powder coating.

Types of painting

Plating (plating) : A method of coating the surface with a thin film of metal.

Plating is mainly used for three purposes: (1) decorativeness, (2) functionality, and (3) anti-corrosion. and chromium plating, and (3) if corrosion resistance is required, zinc plating and chromate treatment are generally used.

In addition, there are three types of galvanizing, which are mainly used for anti-corrosion measures: electro-galvanizing, hot-dip galvanizing, and impact galvanizing.

Types of plating

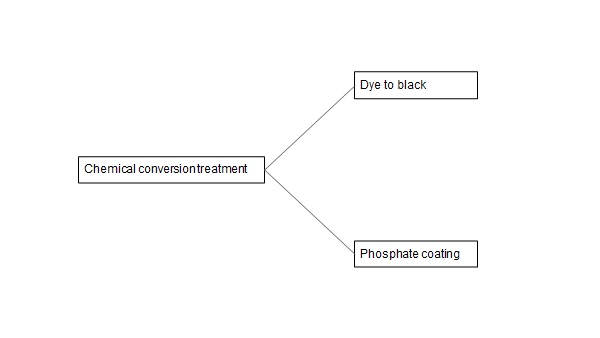

Chemical conversion treatment:In this method, the surface of the spring is treated with chemicals to cause a chemical change, and the film formed on the surface is used as a means of rust prevention .

Plating can only treat the surface well, but chemical treatment has the advantage of being able to apply a rust-preventive coating evenly because the chemical penetrates and treats.

There are two types of chemical treatment methods mainly used for springs: iron oxide chemical treatment called blackening and phosphate chemical treatment called parkerizing .

Click here for details of types of chemical conversion treatment ↓

> Spring chemical conversion treatment

■ Example of spring secondary processing

> YouTube channel [Spring comprehensive manufacturer "Fusehatsu Kogyo"] Video is being distributed!

■PR(Japanese Page)

>Sunday Mainichi "Company style" published.

>Sankei Shimbun full-page color advertisement

>Monthly PHP Business THE21 "Following the topical business people" published.

>It was published in "Premonition of a hit!"

>Published in the ISO information magazine "Intertek News".

> “Higashi-Osaka Industrial Photo Exhibition” at the former Kawazumi family of the Higashi-Osaka Shimbun Photo exhibition of factories and public baths, as well as anti-infection products

>Higashi-Osaka Shimbun corner of Fusehatsu Industry exhibiting photos of springs and machinery

>Kinzoku Sangyo Shimbun Fusehatsu Industry Developing new customers through SNS

Became an official sponsor of the professional basketball team "Osaka Evessa"!

>Blog "Spring and Kurasu" [Became an official sponsor of a professional basketball team]

https://www.fusehatsu.co.jp/

![]()