|

When designing a spring

The point is, "First of all, I want you to know this."

Let's take a general coil spring as an example.

Spring design procedure 7 points

Point 1 Check the space and mounting position for mounting the spring.

Few people start designing with springs when designing machines. It is often designed near the end.

After all the design of the housing and surrounding parts is completed, the spring design will be done within the remaining space.

Let's check how big and shape the spring can be designed, and also whether there is a space for stable mounting.

It is designed to perform the required functions (load, etc.) in the limited space.

Although the spring was designed, there are cases where the mounting position is unreasonable and the spring has a complicated shape, resulting in high cost.

Point 2 Check how to use the spring and the environment in which it is used.

Mainly check the following points.

① Is the spring used repeatedly (dynamic use), or is it almost never repeated once it is attached (static use)?

② What is the temperature around the use of the spring?

③ Would you like to use it in a salty environment? Indoor or outdoor?

④ When using a guide rod for mounting, it is in contact with the spring.

⑤ If the spring breaks, can it be easily replaced?

Point 3 What is the required spring constant and load?

It would be nice if we could calculate the required spring constant and load and get the exact values.

In some cases, it can only be expressed sensuously, such as "stronger and weaker than the current spring."

In that case, if there is a reference spring sample, the load can be measured with a spring tester, so the approximate required load can be estimated.

It is easier to quantify, such as making it 10% stronger than the spring sample.

If you don't have a spring sample, make a "sample" and use it as a reference to make it stronger, weaker, or simulate.

Alternatively, if you have a standard spring that looks good, you can buy it first, try it, and then determine the exact required load.

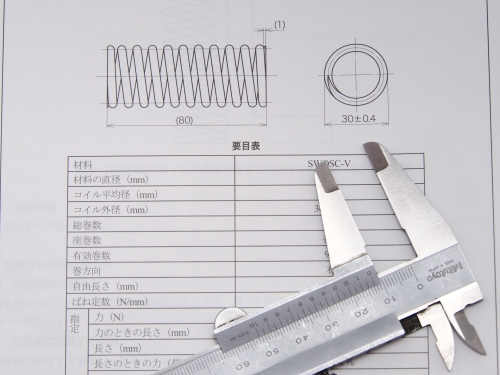

Point 4 Order of items to be examined for spring design

If you empirically consider in the following order, you can design smoothly.

① Material

② Free length

③Coil average diameter

④ Effective number of turns

⑤ Wire diameter

⑥ Terminal shape

First, ① select the material.

Next, ② free length and ③ coil average diameter are calculated from the dimensions of the spring mounting space.

④ For the effective number of turns, consider the dimensions at the time of close contact. Volume 3 or more is recommended.

The spring constant is determined by the combination of three parameters: ③ average coil diameter, ④ effective number of turns, and ⑤wire diameter.

Therefore, if ③ the average coil diameter and ④ the effective number of turns are determined, ⑤ the wire diameter will inevitably be determined.

Finally, ⑥ examine the terminal shape.

You can easily calculate the load and spring life by entering the values in the spring calculation software.

When there are multiple design proposals, it is common to select a design with a low spring constant.

The reason is that if the mounting position varies, the lower the spring constant, the smaller the change in load, and the more stable the spring function.

Point 5 Consider surface treatment

In many cases, you just apply rust preventive oil.

Depending on where the spring is used, consider plating, painting, chemical conversion treatment, etc.

Note that some materials, such as oil tempered wire, are not suitable for plating (hydrogen embrittlement is severe and easily breaks).

Also, when plating or painting the tension spring, the contact area cannot be surface-treated and the contact area will rust.

A special plating jig is required to prevent rust, which increases the cost.

Point 6 Manufacturing cost

Care must be taken when designing, as manufacturing costs will be high in the following cases:

① Design with materials with special specifications (deformed lines, etc.) and materials with a small distribution volume.

It is often not produced unless it is produced from scratch. In that case, material production will be in the hundreds of kilograms.

Even if only one spring is made, the material cost will be several hundred kilograms.

② Requires accuracy that exceeds JIS standard 1st grade for springs.

After mass production with a machine, it is necessary to inspect all of them or manually center them one by one, which may result in high cost.

When precision tolerances are added to the load, if precision tolerances are also included in all other dimensions, mass loss may occur during mass production, or mass production may not be possible.

This is because the tensile strength of the material also varies, and even if it is manufactured according to the dimensions, the load may not fall within the tolerance.

In that case, it is necessary to create adjustable dimensions (generally, the free length is used as a reference value).

③ Weld the spring.

The spring material is high carbon steel. It is a material that breaks quickly when welded. Spring materials are not suitable for welding.

In order to prevent breakage, process equipment that "tans" after welding is required.

In addition, a special testing machine may inspect all welded parts, which is more costly than normal welding.

Point 7 Throw the design to the spring shop

Specify only points 1 to 3 and ask a specialized spring manufacturer to help you with the design.

|

![]()

![]()